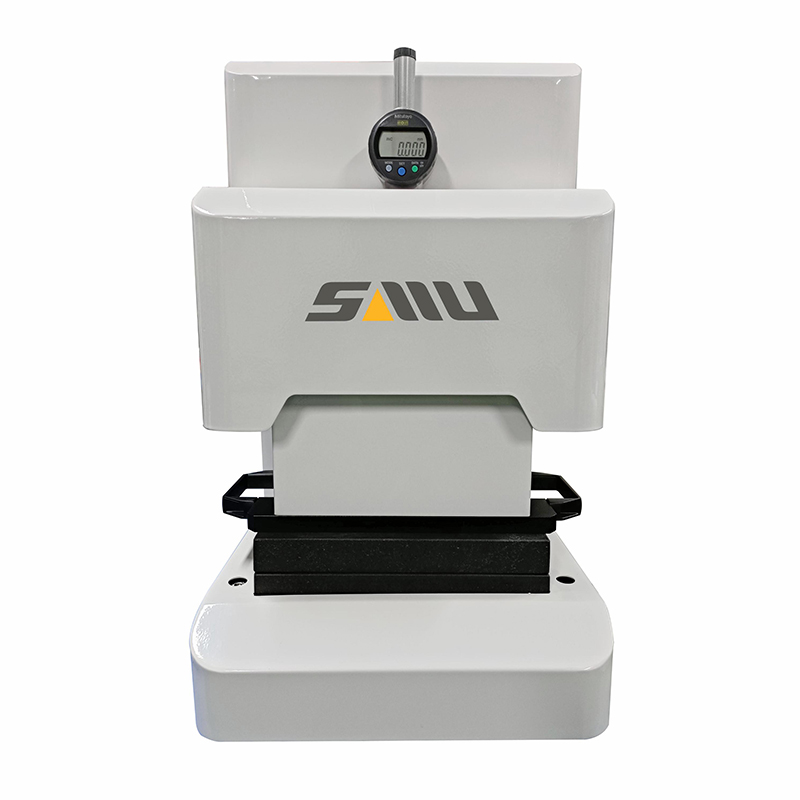

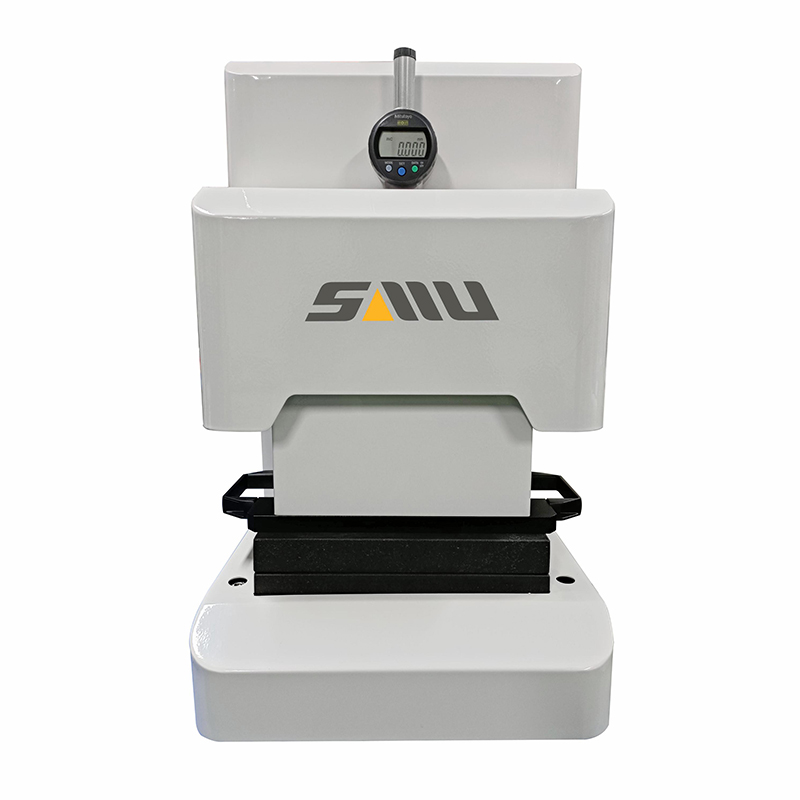

Non-Contact Coordinate Measuring Machine Company – PPG-20153M (The manual type PPG thickness gauge) – Chengli

Non-Contact Coordinate Measuring Machine Company – PPG-20153M (The manual type PPG thickness gauge) – Chengli Detail:

Technical parameters

|

S/N |

Item |

Configration |

|

1 |

Effective test area |

L200mm × W150mm |

|

2 |

Thickness range |

0-30mm |

|

3 |

Working distance |

≥50mm |

|

4 |

Reading resolution |

0.001mm |

|

5 |

Flatness of marble |

0.003mm |

|

6 |

Measurement error of one position |

Put a 5mm standard gauge block between the upper and lower pressure plates, repeat the test 10 times at the same position, and its fluctuation range is less than or equal to 0.003mm. |

|

7 |

Comprehensive measurement error |

A 5mm standard gauge block is placed between the upper and lower pressure plates, and the 9 points evenly distributed in the pressure plate are measured. The fluctuation range of the measured value of each test point minus the standard value is less than or equal to 0.01mm. |

|

8 |

Test pressure range |

500-2000g |

|

9 |

Pressure transmission mode |

Use weights to pressurize |

|

10 |

Sensor |

Altitude dial indicator |

|

11 |

Operating environment |

Temperature:23℃±2℃ Humidity:30~80% |

|

Vibration:<0.002mm/s,<15Hz |

||

|

12 |

Weigh |

40kg |

|

13 |

***Other specifications of the machine can be customized. |

|

Product Description

PPG Lithium Battery Thickness Gauge is a series of instruments developed by Chengli Company for the requirements of customers in the new energy industry to rapidly detect battery thickness under specific pressure. It overcomes the problems of unstable pressure, poor adjustment of the parallelism of the splint, and low measurement accuracy when measuring the thickness of lithium batteries on the market. This series of instruments has fast measurement speed, stable pressure and adjustable pressure value, which greatly improves the measurement accuracy, stability and measurement efficiency.

Introduction

The PPG is suitable for measuring the thickness of lithium batteries, as well as measuring other non-battery thin products. It uses weights for counterweight, so that the test pressure range is 500-2000g.

Operating steps

2.1 Put the battery into the test platform of the thickness measuring machine;

2.2 Lift the test pressure plate, so that the test pressure plate naturally presses down for testing;

2.3 After the test is completed, lift the test press plate;

2.4 Remove the battery until the whole test step is completed.

The main accessories of the equipment

3.1.Sensor: Altitude dial indicator.

3.2.Coating: Stoving varnish.

3.3.Material of parts: steel, grade 00 jinan blue marble.

3.4.Cover material: Steel and aluminum.

Power Supply

AC220V/50HZ

AC110V/60HZ

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for Non-Contact Coordinate Measuring Machine Company – PPG-20153M (The manual type PPG thickness gauge) – Chengli , The product will supply to all over the world, such as: Azerbaijan, Mexico, UK, The quality of our products is equal to OEM's quality, because our core parts are the same with OEM supplier. The above products have passed professional certification, and we not only can produce OEM-standard products but we also accept Customized Products order.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.